Biogas service

Service

We don´t call it a day until the plant is up and running

Whether maintenance, optimization or compliance with the 44th BImSchV – we take a close look at your plant and always know what needs to be done. Because even if the trouble-free and efficient operation of your biogas plant is our main focus, we will not recommend services that are not necessary or useful. That is why we have designed our services to be as transparent as possible. What’s more, with us you only pay for what you have actually commissioned.

Technical CHP service

Only well functioning combined heat and power plant gets the best out of your biogas plant. But even the most powerful and technically advanced unit should be serviced regularly. So that you won´t be surprised by a sudden failure, we also offer a complete service. From maintenance, inspection and servicing of the gas engines, to fault clearance and the assured supply of spare parts (regardless of whether it’s a screw or a replacement engine), you get everything. And best of all: with our immediate service, our team will be at your site within the shortest possible time (even on Sundays and public holidays).

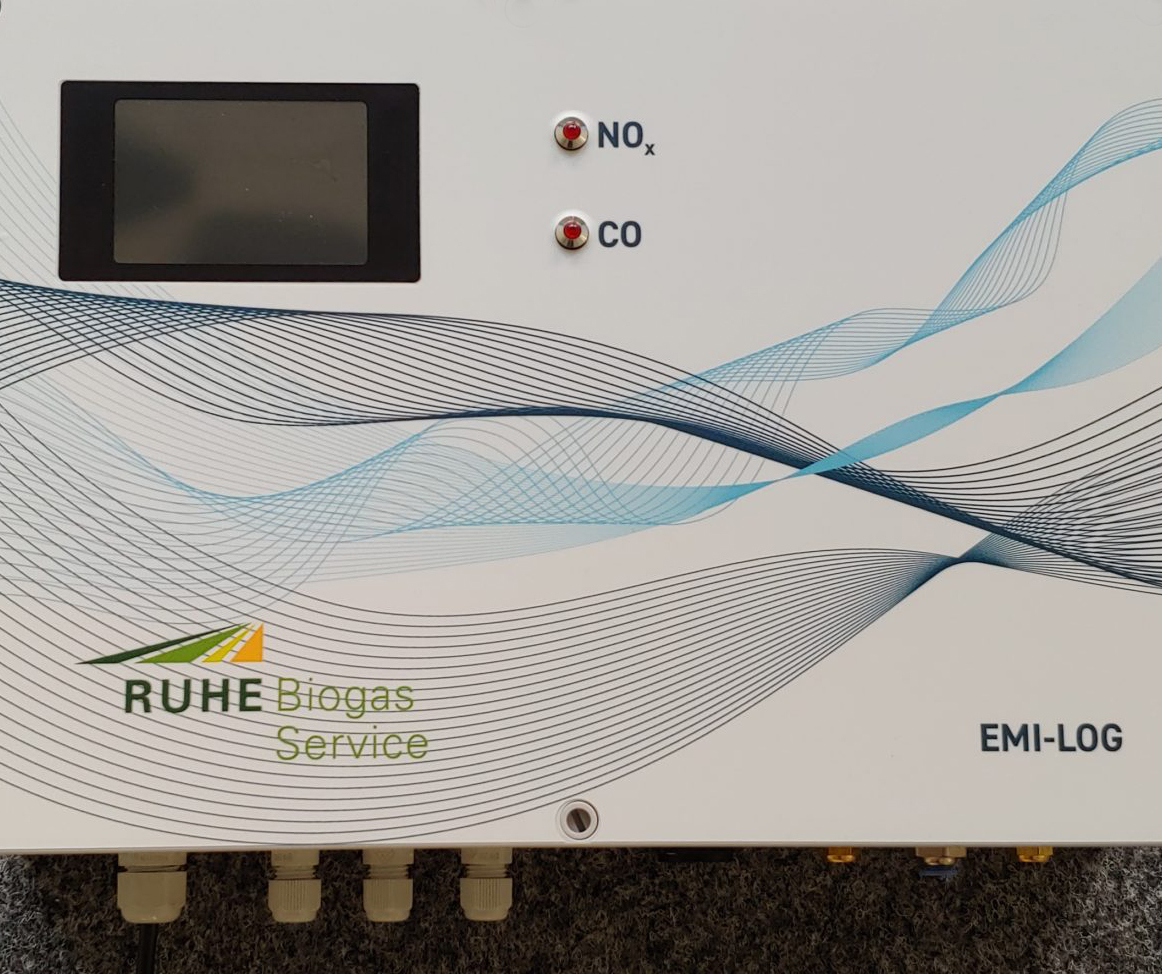

Emission and catalyst monitoring for compliance with the 44th BImSchV

With the introduction of the 44th Federal Immission Control Ordinance in June 2019, operators of biogas plants with lean-burn gas engines with a rated thermal input of ≥ 1 MW must always pay attention to and be able to prove continuous compliance with the nitrogen oxide limits as well as the effective operation of the catalytic converters of their plant engines. The easily retrofittable EMI-LOG with CO sensor meets these requirements and at the same time reduces the documentation effort due to the automated storage of the measurement data and downtimes. Also available are an annual report and monthly reports, which you can also submit as evidence to your competent authority.

This self-sufficient solution, which is independent of the engine manufacturer, simultaneously monitors the carbon monoxide and nitrogen oxide values of the gas engines and stores the measurement data in the form of averaged values and an error log. You can follow all relevant values (NOx and CO) live on the integrated display. As an official service partner of Emission Partner, we will be happy to advise you on this intelligent solution and support you during installation and regular maintenance with our suitable service packages.

You can also obtain further information on EMI-LOG at: katalysatorüberwachung.de

Technical plant service

From our 20 years of experience, we know what is important in the reliable and efficient operation of your biogas plant and what tasks may arise. To prevent these from occurring in the first place, our experienced and highly qualified service team takes care of the regular maintenance and inspection of all mechanical components of your plant. This includes, for example, the maintenance and replacement of agitators, pumps and compressed air technology as well as the optimization of maintenance schedules and technical equipment on site.